- 24 North Parganas, Kolkata, West Bengal

- GST NO. : 19ADCPD2551L1ZM

- +91-9830531350, +91-9830531372

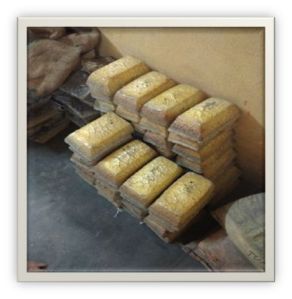

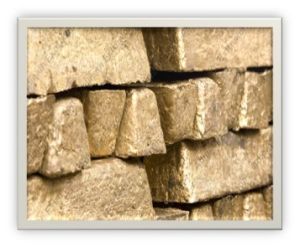

Zinc Alloys Ingot

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Size | 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, ASTM, BS, DIN |

| Type | Zinc Alloy Ingot |

| Material | Zinc Alloy |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Zinc is a common additive to base metals to create Zinc Alloys. These alloys are formed and worked into various applications depending on the types of metals that are alloyed together. Zinc is usually considered a weak base metal. It is very brittle due to which it is used in Coating & Galvanizing applications where other metals will take on Load Bearing Duties. When Zinc is alloyed with other stronger metals, it can attain a higher impact strength. The alloyed metal also provides electrochemical properties and is extremely malleable in extremely malleable in lower working conditions between 2000 F - 3000 F. Due to these properties, the metal is used in more complex fabrication and galvanizing processes. Zinc also has good corrosion resistance properties. Zinc Alloys have varied uses based on industries. In addition, the purity level of zinc also decides which application the Zinc would be used in. Zinc Alloys are used in various applications like Automotive Industries where they are used for coatings for galvanized steel. Galvanizing Steel Parts and components helps in preventing corrosion. In medical field, zinc alloys are used since they are considered environmentally safe. In Buildings & Constructions, Zinc alloys are used in a wide range of applications as products. They are used as solder, household fittings and as coating on roofing & cladding products. Zinc Alloys find use in marine applications where they are used as sacrificial anodes for marine vessels and other applications that are exposed to saltwater environments. The Following table lists the Zinc Alloys Manufactured by us: -

|

General Designation |

ASTM Designation |

Percentage Composition |

||||||||

|

|

|

Al |

Cu |

Mg |

Fe Maximum |

Pb Maximum |

Cd Maximum |

Sn Maximum |

Ni |

Zn |

|

Zamak 2 |

AC43A |

3.5-4.3 |

2.5-3.0 |

0.02-0.05 |

0.100 |

0.005 |

0.004 |

0.003 |

--------------- |

Remainder |

|

Zamak 3 |

AG40A |

3.5-4.3 |

0.25 Max |

0.02-0.05 |

0.100 |

0.005 |

0.004 |

0.003 |

|

Remainder |

|

Zamak 5 |

AC41A |

3.5-4.3 |

0.75-1.25 |

0.03-0.08 |

0.100 |

0.005 |

0.004 |

0.003 |

|

Remainder |

|

Zamak 7 |

AG40B |

3.5-4.3 |

0.25 Max |

0.005-0.02 |

0.075 |

0.003 |

0.002 |

0.001 |

0.005-0.020 |

Remainder |

|

ZA - 8 |

|

8.0-8.8 |

0.8-1.3 |

0.015-0.030 |

0.075 |

0.006 |

0.006 |

0.003 |

|

Remainder |

|

ACuZinc5 |

|

2.5-3.3 |

5.0-6.0 |

0.025-0.05 |

0.075 |

0.005 |

0.004 |

0.003 |

|

Remainder |

|

ZA - 12 |

|

10.8-11.5 |

0.5-1.2 |

0.020-0.030 |

0.05 |

0.005 |

0.005 |

0.002 |

|

Remainder |

|

ZA - 27 |

|

25.5-28.0 |

2.0-2.5 |

0.012-0.020 |

0.07 |

0.005 |

0.005 |

0.002 |

|

Remainder |