- 24 North Parganas, Kolkata, West Bengal

- GST NO. : 19ADCPD2551L1ZM

- +91-9830531350, +91-9830531372

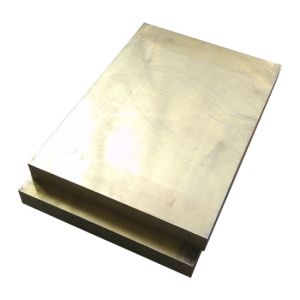

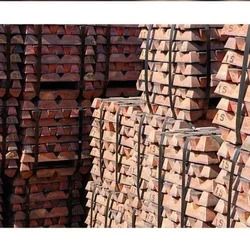

Phosphorous Bronze Split Bush

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Country of Origin | India |

| Type | Linear Bush With Sleeve Bearings |

| Material Grade | BS, IS, ASTM Grades |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Phosphorous Bronze Split Bushes are cast as per IS:28-1985 Specification. They are required as Cam Wheel Split Bush & Bush for Journal Bearings. Split Bronze Bearings are required in multiple industrial applications. They aid in absorption of shock, reduction of vibration and noise. The split bushing design could eliminate the need for additional lubrication methods as well as reduce the amount of maintainence needed for optimal operation. Split Bushings are also used where a 2 piece housing is present or where quick assembly and easy installation is required. There are 3 types of split bushings namely perfect halved bushings, matched halved bushings and bushings that are split after machining. Perfect halved split bushings will yield 2 halves of the exact same size. These halves will also match with any other halves manufactured under the same specification. With perfect half split bushings, the halves are interchangeable with any of the other same size halves. Matched halved bushings will match with the corresponding opposite half that had been manufactured with it. Split after machining are the most economical of the 3 types. The material requirement for these parts are the same as non split bushings where the only extra effort lies in the added operation of cutting. The matched and perfect halved bushings start with a larger stock size than what would be used for a split after machining bushing. The bar stock is cut before machining after which they are welded together. The larger beginning stock size will make up for the size loss during the cutting stage. After welding the 2 stock bar halves are machined to finished dimensions. The 2 halves are then separated. This leaves us with 2 halves that will comoplete a 360 Degree Circle. Perfect halved bushings are the least economical and generally are only specified where the split line is critical to the application. They are manufactured in a similar fashion as the matched halves but special attention is paid to make sure that each half is split at the exact centerline and at the same angle as all the other pairs. The process results in halves which are interchangeable amonst one another.